The importance of approvals

The importance of the homologation of welding processes and welders.

How long do my company procedure and welder approval documents last?

Author: Nacho Chinchilla, Integration and Welding Engineering, Consulting and Training.

A Company Approval procedure, i.e. the set of documents comprising the WPS, WPQR, WPQO, etc. do not have a temporary expiration date.

This means that when a company certifies a certain work procedure, it is generally valid for life, as long as there are certified welders on that procedure who are the ones who provide the real durability of the correct use of the document.

This does not mean that a contracting company may not request additional or specific tests before, during or after the execution of certain works at any given time, or due to the needs of the project management.

Of course, there are also variables with special requirements for a given validity, depending on the rule that supports it.

A Welder or Operator certification is controlled by the reference standard itself, based mainly on the material or possible specific requirements based on the production sector, be it Railway, Shipbuilding, Nuclear, Construction, etc.

In general, the material-based regulations focus on a validity of 2 or 3 years of coverage as long as there is a biannual verification that the worker continues with the execution of welding work covered under the reference procedure.

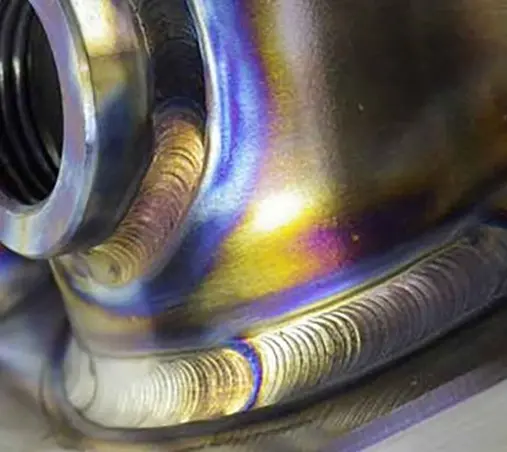

Therefore, it must be certified that welding continues under the same conditions, respecting and passing the appropriate quality controls to keep them in force.

Of course this does not exempt that in a particular work, due to the importance of the same or by requirement of the contractor, it is that they have to do some test or sample coupon necessary and specific for that work.

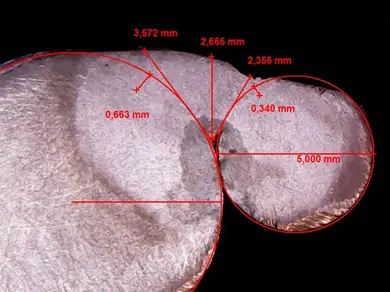

For all these reasons, a complete technical study of the specific industrial need must be carried out.

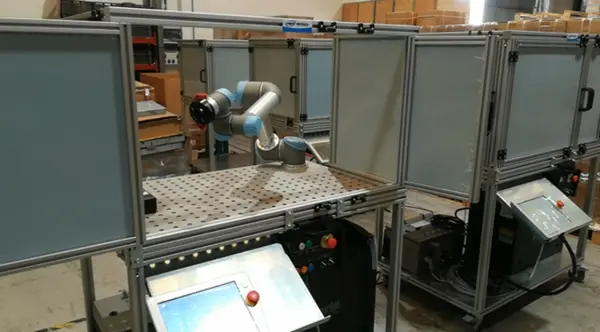

Our experience and knowledge of the regulations and processes, will allow you to obtain the maximum possible coverage with the minimum investment, for which we will accompany you throughout the process of preliminary study, initial welding tests, and especially in the execution of the test coupons resulting from this study, to ensure the overcoming of all subsequent quality control with all laboratory tests that mark the reference standards, finally offering the certification and approval documents that guarantee to third parties all this process. Ask us how.

For more information on this product, please contact us.

Share this post: