Stud welding

Welding systems for bolts, studs, nuts and accessories.

PS-3

These two guns allow precise welding of ignition tipped studs on traced surfaces or marked centres using the spring pressure of the gun.

PS-9

The PS-9 stud welding gun with an innovative user assistance system using a multi-colour LED display (patented utility model no.: 20 2009 012 370.7) has been designed for use with the new BMS-9 stud welding machine.

PS-1K

The handy and user-friendly PS-1K welding gun achieves extreme bolt positioning accuracies of +/- 0.1 mm thanks to precision mechanisms with sequences of movements that do not produce a backlash effect.

BMS-10N / BMS-10NV

High-performance equipment that can be used both manually and to make the leap to process automation, even with guns with automatic pin feed.

BMS-9 / BMS-9V

Inverter equipment that recognises the mains input voltage and the type of gun connected.

BMS-8N / BMS-8NV

Equipped with microprocessor and Digital display with parameter control.

BMK-16i

Multiprocess unit BMK-16i is a universal inverter power source recommended for different welding processes.

DA WELDING

The “STUD WELD” welding process by means of ARCO, provides high quality and resistance in applications in connectors, bolts and terminals with diameters between 6 and 25 mm, providing solutions in construction, boilermaking, piping, etc.

- More info

PH3N

The user-friendly PH-3N stud welding gun offers a maximum of technical operating advantages thanks to its compact and very slim design.

BMK-12W

Easy to use equipment that can handle welding of bolts with diameters between 2 and 11 mm with metrics of M3-M12.

KTS-4000 CNC

The CNC stud welding machine XXXL KTS-4000 with a usable working area of 2050 mm x 4200 mm (XY) allows the welding of studs according to all known stud welding processes.

KTS-2600 CNC

This large-scale CNC stud welding machine features high performance and precision.

KTS-1550 W CNC

This versatile CNC stud welding machine is characterised by high performance and precision.

KTS-1550 CNC

The KTS-1050 CNC capacitive discharge welding machine is an entry-level model that ensures maximum accuracy, productivity and reliability in automatic stud welding applications.

KTS-1050 CNC

The KTS-1050 CNC stud welding machine is an entry-level CNC model that ensures maximum accuracy, productivity and reliability in automatic stud welding applications.

PTS-500 NC

The PTS-500 NC stud welding machine allows studs and pins from 3 - 10 mm in diameter and 40 mm in length to be welded precisely and fully automatically according to all known stud welding processes.

SK-5AKS

This multifunctional welding head integrates all elements for gap and contact welding in one compact housing and allows switching between the two welding processes in a matter of seconds.

SK-5AP

The slim and compact SK-5AP stud welding head has a unique stud feed system and can be quickly converted for other stud diameters.

PTS-2

The PTS-2 is a powerful and economical stud welding machine for stationary welding of various types of welding fixtures.

SK 5 T-NUT

These robust bench-mounted systems feature easy handling, high accuracy in weld stud placement and cost-effective performance even with small production runs and single batches.

DA

Bolts manufactured in SOYER's German plant, under the strictest quality systems with German and European raw materials.

SRM

Bolts manufactured in SOYER's German plant, under the strictest quality systems with German and European raw materials.

CD

Bolts manufactured in SOYER's German plant, under the strictest quality systems with German and European raw materials.

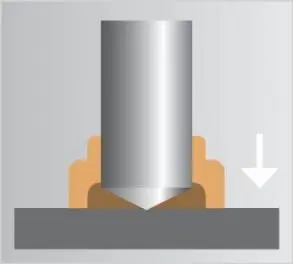

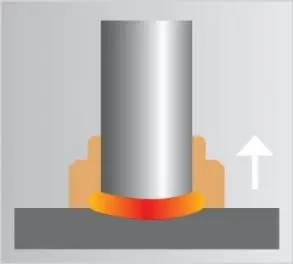

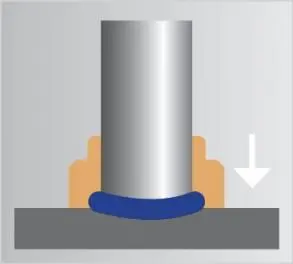

This product line defines a set of manual, automated and robotized solutions for the effective joining of different elements in any base material.

It is a fast and effective process that has different joining methods based on the specific needs of the production process.

From Synerbot we put at your service all our experience starting from the design phase, implementation of equipment and welding solutions along with their associated applications, the whole process of education and training appropriate to their industrialization.