Aluminium welding

Aluminium welding. Aluminium as a base material

Author: Nacho Chinchilla, Integration and Welding Engineering, Consultancy and Training.

Aluminium is one of the metals with more projection in the metallurgical industry thanks to the constant development of materials engineering, which achieves alloys with physical-mechanical resistance comparable to those of other more widely used materials such as some conventional steel alloys.

It is a more malleable, ductile and lighter material than any other, so it is essential to know the alloys available on the market for the manufacture of our components.

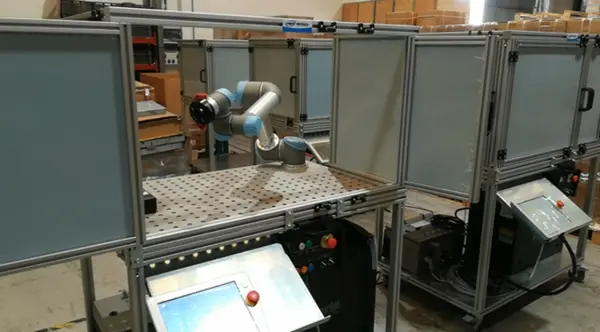

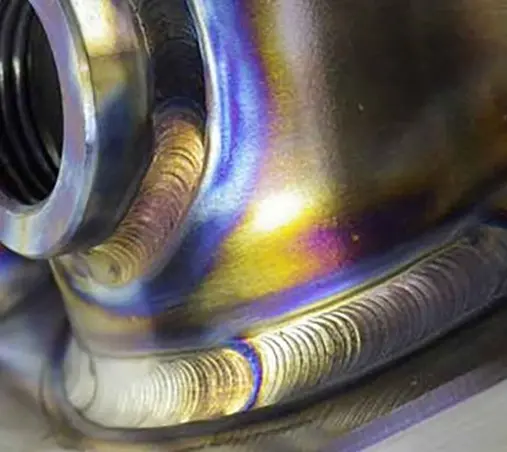

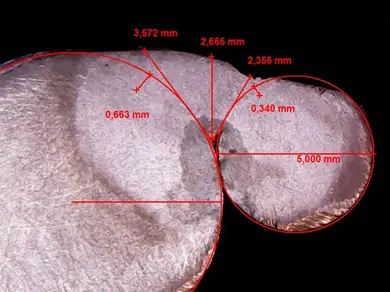

From a welding point of view, with the appropriate technical conditions and using the predefined synergic curves in our SYNERBOT ROBOTIC welding equipment, practically all commercial aluminium alloys can be welded using the GMAW and GTAW processes.

When we talk about aluminium, we always think of a white, pleasant, cool, lightweight, corrosion-resistant, easily machinable and durable metal.

It is increasingly used in all industrial sectors, Aeronautics and Aerospace, Automotive, Railway, Sports, Ornamental, Structural, Construction, etc.

In terms of its weldability, the most suitable welding process for the construction process must be predefined in advance, but the low melting point of aluminium, approx. 658º C. and the high melting point of the Alumina Al2O3 surface protective layer, which requires melting temperatures of approx. 2100º C., must be taken into account.

That is why a highly versatile and precise process and equipment is required to obtain the best welding processes in your production.

In addition, in order to proceed with welding, the most suitable filler material must be predefined based on the specific aluminium alloy to be used for our specific fabrication.

Currently, there are heat-treatable and non-heat-treatable aluminium alloys on the market, the latter being the most common and most commonly used in processes involving welding.

Alloys ranging from pure Aluminium, or alloyed with Magnesium (Mg), Manganese (Mn), Titanium (Ti), Copper (Cu), Chromium (Cr), Silicon (Si), etc. such as alloys type 1100 1350 – 3003-5005-5052-5083-5086-5454-5456

Within the heat-treatable alloys, the hardest and strongest alloys with different percentages of metallic chemical alloys of those mentioned in the previous group and which are widely used in places of great responsibility where there are high mechanical requirements, high resistance to corrosion, structural engineering etc., we find the types 2024 – 6061 – 7075.

For more information on this product, please contact us.

Share this post: