Homologation of welding processes and welders

The importance of the homologation of welding processes and welders

Author: Nacho Chinchilla, Integration and Welding Engineering, Consulting and Training.

In an increasingly competitive industrial environment with high quality control requirements, the assurance of our processes and manufactured products is an industrial obligation for the sustainability of the commercialization of the manufactured products.

For this purpose, there are different codes and standards for the control of all these industrial processes and procedures, with different degrees of compliance depending on the sector and production capacity. All of them have their own standards and codes that manage the specific conditions for the control of production and industrial processes.

This is a reality in all production sectors, Metal Construction, Railway, Construction and Civil Works, Shipbuilding, Pressure Vessels, etc.

In all of them and independent of the specific conditions, there is a core discipline and coinciding mandatory compliance which is the provision in the company itself of Procedure of approval of company procedure and certification of welders.

But what does each of them mean?

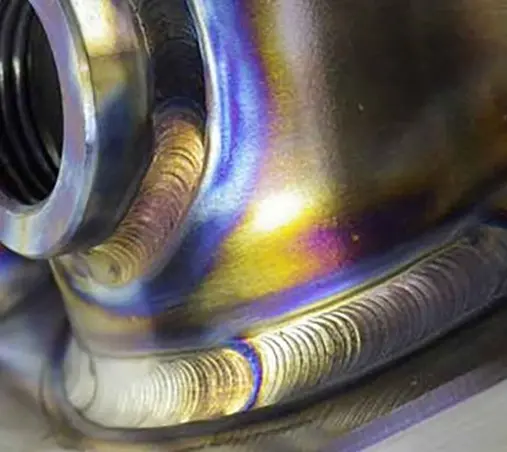

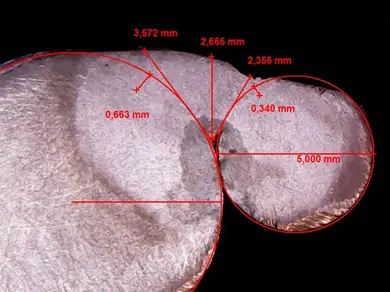

- Homologation of Company procedures, (WPS, PQR, WPQ) to guarantee the production assurance by following and complying with the pre-established parameters, and proven by means of quality tests and control tests, that mark the corresponding acceptance standard and that allow to demonstrate to third parties that all welding processes are controlled at a technical and execution level, with the assurance of their mechanical integrity and complying with the appropriate control and verification standards.

- Essential requirement for companies.

- WPS is the welding procedure specification.

- PQR is the procedure qualification record.

- WPQ is the welder skills qualification.

- Welder and operator qualification, to guarantee the operator’s skill in the execution of correct welds, and to ensure that each operator knows, respects, and performs as many operations as are included in this procedure, which certifies that different operators, in different workplaces, executing the same procedure obtain the same quality results where testing is sought.

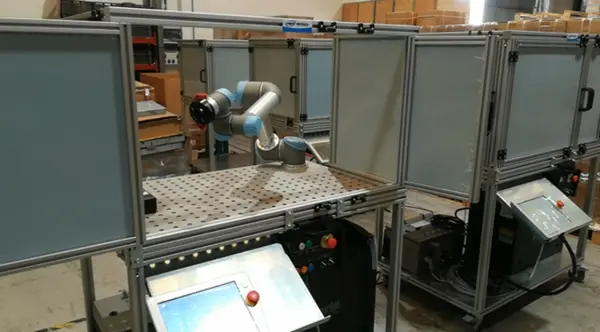

At SynerBOT-GalaGar, we can carry out a study of your specific needs, providing you with our experience and presenting an economic technical study, accompanying you throughout the development and execution of the whole process of Homologation and Certification.

For more information on this product, please contact us.

Share this post: